As a leading 5056 Aluminum Strip Supplier and 5056 Aluminum Strip Manufacturer, we offer high-quality aluminum strips with detailed specifications to meet your industrial needs. Explore our range of 5056 aluminum strips for sale and find the right aluminum strip product for your project.

5056 Aluminium Strip Specifications

Standards : ASTM B209 / ASME SB209

Temper :O, H12, H14, H16, H18 (custom tempers available)

Thickness: 0.15~10mm

Width: 10~500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

5056 Aluminum Strip Data Sheet

Chemical Composition of 5056 Aluminum Strips

| Element | Range (%) |

|---|---|

| Al | Balance |

| Mg | 4.5 – 5.5 |

| Cr | 0.05 – 0.20 |

| Fe | ≤ 0.7 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.10 |

| Si | ≤ 0.30 |

| Zn | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

There are some differences in the chemical composition of aluminum products from different aluminum manufacturers, but they are all within a certain range. If you want to know more, please contact us directly!

Mechanical Properties of 5056 Aluminum Strip

| Property | Temper O | Temper H12 | Temper H14 | Temper H16 | Temper H18 |

|---|---|---|---|---|---|

| Tensile Strength | 310 MPa (45 ksi) | 345 MPa (50 ksi) | 379 MPa (55 ksi) | 414 MPa (60 ksi) | 450 MPa (65 ksi) |

| Yield Strength | 275 MPa (40 ksi) | 310 MPa (45 ksi) | 345 MPa (50 ksi) | 379 MPa (55 ksi) | 414 MPa (60 ksi) |

| Elongation | 12% | 10% | 8% | 7% | 6% |

| Brinell Hardness | 90 | 100 | 110 | 115 | 120 |

Choose us for reliable 5056 Aluminum Strip solutions that meet your specific needs with precision and quality.

Physical Properties of 5056 Aluminum Strip

| Property | Temper O | Temper H12 | Temper H14 | Temper H16 | Temper H18 |

|---|---|---|---|---|---|

| Density | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ | 2.65 g/cm³ |

| Melting Point | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C | 610°C – 650°C |

| Thermal Conductivity | 122 W/m·K | 122 W/m·K | 122 W/m·K | 122 W/m·K | 122 W/m·K |

| Electrical Conductivity | 30% IACS | 30% IACS | 30% IACS | 30% IACS | 30% IACS |

| Modulus of Elasticity | 70 GPa | 70 GPa | 70 GPa | 70 GPa | 70 GPa |

| Coefficient of Thermal Expansion | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C | 22.8 µm/m·°C |

Applications of 5056 Aluminum Strip Metal

5056 Aluminum Strip is highly versatile and used in various industries:

Marine Industry: Due to its excellent corrosion resistance, it is ideal for marine environments, including boat hulls and fittings.

Aerospace: Used in aerospace components that require high strength and resistance to environmental factors.

Automotive: Applied in automotive parts where strength and durability are critical.

Industrial Applications: Utilized in structural components and other high-stress applications.

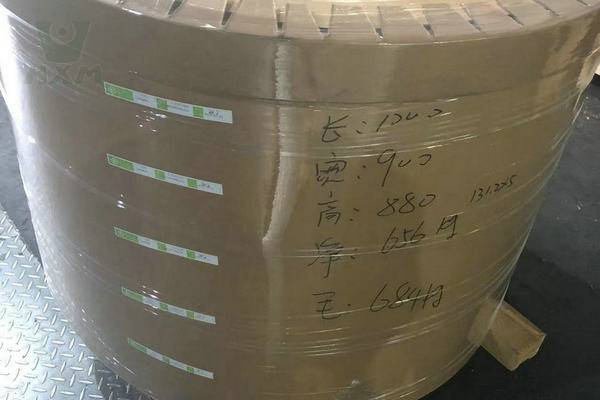

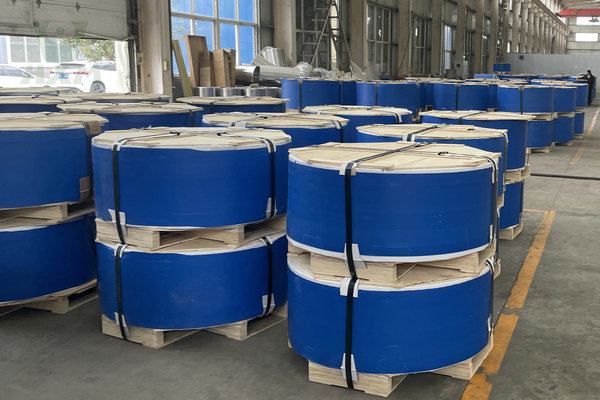

5056 Aluminum Strip Packages

The following is our company’s standard aluminum strip export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

What Is 5056 Aluminum Strip?

5056 Aluminum Strip is a high-strength aluminum alloy known for its exceptional mechanical properties and excellent corrosion resistance. It is widely used in marine, aerospace, automotive, and industrial applications where durability and performance are crucial.

At HXM, we offer a wide range of 5056 aluminum strips for Sale, catering to both standard and custom requirements. Our products are manufactured to the highest standards, ensuring reliability and performance.

Choose us for your 5056 aluminum strip needs and experience the highest quality products and exceptional service.

How Does 5056 Aluminum Strip Compare To Other Aluminum Strip?

5056 aluminum strip is highly regarded for its high strength and excellent corrosion resistance, making it suitable for demanding applications such as marine and aerospace environments. It has a higher magnesium content than 6061 and 3003, which contributes to its excellent strength and corrosion resistance, but may also result in slightly reduced machinability.

6061 aluminum strip offers a balance of strength, machinability, and corrosion resistance, making it suitable for structural applications and common in industries such as construction and automotive.

3003 aluminum strip is known for its excellent corrosion resistance and formability but has lower strength compared to 5056 and 6061. It is often used in applications that require good formability and corrosion resistance, such as cookware and chemical equipment.

This comparison highlights the advantages and limitations of 5056 aluminum strips over other common aluminum alloys to help you make an informed decision based on your specific application needs.

How Can I Get A Sample Of 5056 Aluminum Strips?

Yes, we can provide samples of 5056 aluminum strips for your testing. We can also provide samples of other materials. If you are not sure whether 5056 or other materials of aluminum strips meet your project requirements, you can contact us to get a sample.

Why Choose Us As Your 5056 Aluminum Strip Supplier?

If you are looking for a manufacturer and exporter of 5056 Aluminum Strip, I think we can be one of your Aluminum Strip suppliers! Here are some reasons why we think you can choose us:

Industry Time: We have been engaged in the metal industry for more than 10 years, with a professional manufacturing and export service team, advanced machinery and equipment, etc.

Competitive Product Prices: Due to our long history in this industry, we have long-term cooperation projects with many steel mills, so the quality and price of our products can be guaranteed. Our internal manufacturing efficiency has been improved, and we can produce more and better aluminum products in the same amount of time, thereby reducing our cost prices.

Excellent Customer Service: For first-time customers, we provide videos and on-site factory visits to increase customer trust. We accept payment methods such as TT, L/C, etc. The product warranty period is 5 years, etc.

Why not give us a chance to serve your project? I believe we can become one of your best and most trusted aluminum strip suppliers!