Why 3003 Aluminum Matters in Modern Construction?

In today’s construction industry, durability, corrosion resistance, and cost-efficiency are key factors when choosing materials for roofing, gutters, and exterior cladding systems. Among various aluminum alloys, 3003 Aluminum stands out as one of the most versatile and widely used options worldwide.

At Huaxiao Metal, we have supplied thousands of tons of 3003 Aluminum coils, sheets, and panels for roofing and architectural applications. Our customers—from construction firms to fabrication workshops—trust 3003 Aluminum for its formability, strength, and weather resistance.

In this blog, we’ll dive deep into why 3003 Aluminum dominates the roofing, gutter, and siding market, covering its metallurgical properties, performance advantages, real-world applications, and how it compares with other aluminum grades.

Looking for 3003 Aluminum Roofing Sheets or Gutters?

Contact Huaxiao Metal today to get a customized quote and technical recommendation for your project.

1. Unmatched Formability: Workability That Saves Time and Money

The Feature: 3003 aluminum possesses exceptional workability, ranking among the best for formability in the entire aluminum alloy family. Its composition allows it to be bent, stretched, and deep-drawn during fabrication without work-hardening excessively or cracking.

The Advantage: This means the material can be easily shaped into complex and intricate profiles—from custom-curved roofing panels to seamless gutter corners—all through cold-working processes.

The Benefit for You:

For Contractors: This superior formability is a game-changer on the job site. Your teams can easily form complex transitions and custom roofing flashing on-site, reducing installation time, minimizing waste, and ensuring a perfect, weather-tight fit every time.

For Distributors: You can confidently offer your customers a material that is less prone to fabrication errors and cracking, leading to higher satisfaction and fewer claims.

Huaxiao Metal Tip:

If your project involves deep drawing, bending, or continuous roll-forming, 3003-H14 Aluminum offers the perfect balance between strength and formability.

2. Superior Corrosion Resistance: Built to Withstand the Elements

The Feature: The primary alloying element in 3003 aluminum is manganese, which significantly enhances its inherent resistance to atmospheric corrosion. Unlike steel, aluminum does not rust. When exposed to the elements, it instantly forms a stable, protective oxide layer on its surface that prevents further degradation.

The Advantage: This self-protecting characteristic means the material remains structurally sound and visually clean even after decades of exposure to rain, snow, sun, and humidity.

The Benefit for You:

This translates directly to a longer service life, minimal to zero maintenance, and a clean, professional appearance that lasts for decades. You’ll never see ugly rust streaks staining siding or walls. It is the very definition of a “fit-and-forget” solution that provides peace of mind for both the installer and the property owner.

Weather-Resistant Performance:

| Environment | 3003 Aluminum Behavior | Service Life |

|---|---|---|

| Coastal regions | Excellent – resists saltwater corrosion | 20–30 years |

| Urban/industrial areas | Excellent – withstands acidic environments | 25+ years |

| Rural/farmland zones | Excellent – minimal oxidation | 30+ years |

Unlike steel or zinc-coated materials that require frequent painting or galvanization, 3003 Aluminum remains corrosion-resistant for decades, even without surface coatings.

Engineering Insight:

When combined with PVDF or polyester coatings, 3003 aluminum sheeting offers enhanced resistance to fading, chalking, and weathering, making it an ideal choice for long-term architectural finishes.

Want to ensure long-term durability for projects in humid or coastal areas?

Consult Huaxiao Metal’s aluminum experts to find the right 3003 aluminum coating system for your environment.

3. The Lightweight Champion: Easier Handling, Lower Structural Load

Comparison of Material Density

| Material | Density (g/cm³) | Relative Weight |

|---|---|---|

| Steel | 7.85 | 100% |

| Copper | 8.96 | 114% |

| 3003 Aluminum | 2.73 | 35% |

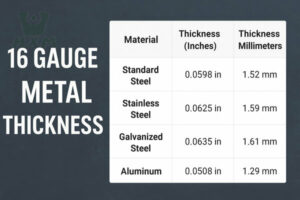

The Feature: At approximately 2.7 g/cm³, the density of aluminum is roughly one-third that of steel.

The Advantage: This makes every coil, sheet, and finished part significantly lighter and easier to manage than its steel counterparts.

The Benefit for You:

For Contractors: Lighter materials mean easier transportation to the job site, faster handling and lifting by smaller crews, and reduced physical strain on your workforce. This directly improves safety, boosts installation efficiency, and can lower labor costs.

For Architects & Engineers: The reduced weight places significantly less dead load on the building’s structure. This is a critical advantage for new constructions with ambitious designs and is especially vital for re-roofing projects on older buildings where structural capacity may be limited.

Huaxiao Metal Advantage: Our 3003 Aluminum roofing sheets are precisely leveled and tension-tested to prevent waviness and ensure structural flatness even under heavy installation stress.

4. Excellent Cost-Effectiveness: Long-Term Value Beats Short-Term Price

The Feature: While the initial purchase price of 3003 aluminum may sometimes be higher than galvanized steel, its total lifecycle cost is dramatically lower.

The Advantage: Its durability and corrosion resistance eliminate the significant long-term expenses associated with maintenance, repair, and eventual replacement that plague other materials.

The Benefit for You:

For Procurement Managers: Position 3003 aluminum as a high-value investment. Its longevity and zero maintenance costs deliver a far superior return on investment for the end-user. The table below illustrates the clear value proposition.

| Feature | 3003 Aluminum | Galvanized Steel |

| Rust Risk | None | High (if coating is scratched) |

| Weight | Lightweight, Easy to Handle | Heavy, Requires More Labor |

| Maintenance | Minimal / None | Requires periodic inspection & painting |

| Lifespan | 30-50+ years | 15-25 years |

| Lifecycle ROI | Excellent | Fair |

Pro Tip from Huaxiao Metal:

Switching from 5052 to 3003 Aluminum for large-scale building projects can reduce total material costs by 15–25% while maintaining performance standards.

Get a free cost analysis now — Contact Huaxiao Metal’s Sales Team

5. Sustainable and Green: The Recyclable Choice for Modern Building

The Feature: Aluminum is 100% recyclable, and it can be recycled indefinitely without losing any of its inherent structural or chemical properties.

The Advantage: The energy required to recycle aluminum is only 5% of the energy needed to produce primary aluminum from bauxite ore. This makes it one of the most sustainable building materials on the planet.

The Benefit for You:

For Architects & Designers: Choosing 3003 aluminum helps you meet modern green building standards, including credits for LEED (Leadership in Energy and Environmental Design). It’s an environmentally responsible choice that appeals to forward-thinking clients and adds tangible value to a project’s profile.

At Huaxiao Metal, we actively support sustainable manufacturing practices by using eco-friendly surface coatings, closed-loop recycling systems, and packaging materials that minimize waste.

3003 Aluminum vs Other Roofing Materials

To make an informed decision, here’s how 3003 Aluminum compares with other common roofing materials:

| Property | 3003 Aluminum | Galvanized Steel | Copper | 5052 Aluminum |

|---|---|---|---|---|

| Weight | Very Light | Heavy | Heavy | Light |

| Corrosion Resistance | Excellent | Moderate | Excellent | Superior |

| Cost | Moderate | Low | High | High |

| Maintenance | Minimal | Frequent | Minimal | Minimal |

| Recyclability | 100% | Partial | 100% | 100% |

For most residential and commercial projects, 3003 Aluminum offers the best balance of cost, longevity, and appearance—especially when installed with professional surface coatings and sealing systems.

FAQs About 3003 Aluminum for Roofing & Gutters

Which tempers are most commonly used for 3003 aluminum alloy in roofing and guttering?

In architectural applications, the most commonly used tempers of 3003 aluminum alloy are H14 and H24.

3003-H14 offers a “semi-hard” strength, providing an excellent balance of strength to resist deformation while retaining excellent formability. This makes it ideal for on-site bending and flashing.

3003-H24, on the other hand, offers higher strength and hardness, making it suitable for siding or precast panels requiring greater rigidity.

Is 3003 Aluminum suitable for coastal areas?

Yes. Its high manganese content provides excellent resistance to saltwater corrosion, making it perfect for seaside or humid climates.

Can 3003 Aluminum be welded or painted?

Absolutely. It can be easily welded using standard aluminum processes and painted with PVDF or polyester coatings for extra protection and color options.

How does 3003 differ from 5052 Aluminum?

5052 offers slightly higher strength and saltwater resistance, but 3003 Aluminum is more economical and perfectly sufficient for roofing, siding, and gutter systems.

3003 Aluminum vs 5052

Why choose 3003 for roofing and guttering over stronger aluminum alloys like 6061-T6?

3003 aluminium alloy has a medium-low strength rating, but its formability and weldability are far superior to high-strength alloys like 6061.

In roofing and guttering applications, extreme strength isn’t a primary consideration; instead, excellent workability is crucial for complex on-site cutting, bending, and sealing.

In addition, 3003 Al alloy is more cost-effective because it doesn’t require additional heat treatment to achieve acceptable strength.

3003 Aluminum Vs 6061

What are the available tempers for roofing materials?

Common tempers include H14 (semi-hard) and H24 (half-hard), offering an optimal balance between strength and flexibility.

Does Huaxiao Metal offer custom fabrication or cutting?

Yes. We provide custom coil slitting, sheet cutting, and surface finishing services to meet your project requirements.

Huaxiao Metal – Your Trusted Partner in Aluminum Solutions.

Whether you’re a construction contractor, distributor, or project engineer, we help you select the right aluminum alloy to optimize performance and cost.

Conclusion: The Clear Choice for Performance and Reliability

From its incredible workability that simplifies installation to its long-term, corrosion-free performance, 3003 aluminum provides an unbeatable combination of benefits for any exterior building application. It’s not just a material; it’s a smart investment in durability, efficiency, and sustainability.

At HXM Aluminum, we don’t just supply this material; we are experts in it. We understand the specific tempers and finishes required to ensure peak performance for your roofing, gutter, and siding projects.

Ready to secure a reliable supply of high-quality 3003 aluminum for your next project? Contact our sales team today for a quick quote on coils or cut-to-length sheets.

Have a technical question? Our material specialists are here to help you choose the perfect temper and finish for your specific application. Let’s build something that lasts.