In today’s competitive market, selecting the right raw material isn’t just an engineering choice—it’s a critical business decision that directly impacts your production line, budget, and supply chain stability. For manufacturers and distributors seeking a reliable, versatile, and cost-effective material, 3003 aluminum consistently proves to be a strategic asset. It’s the workhorse alloy that gets the job done without expensive surprises.

This is not just a technical overview. This is a procurement-focused guide designed to give you the data, application insights, and supply chain confidence you need to strategically source 3003 aluminum for your business.

What Is 3003 Aluminum?

3003 aluminum is a non-heat-treatable alloy primarily composed of aluminum and manganese. It belongs to the 3000 series, which is known for superior corrosion resistance and moderate strength.

It contains approximately 1.0–1.5% manganese, which enhances its strength by about 20% compared to the 1100 series pure aluminum. This makes it ideal for general-purpose applications where formability and corrosion resistance are more important than high strength.

Key identifiers:

Standard designation: AA 3003 / EN AW-3003

UNS number: A93003

Main alloying element: Manganese (Mn)

Temper designations: O, H12, H14, H16, H18, etc.

Typical product forms: Sheet, Coil, Strip, Tube, Bar

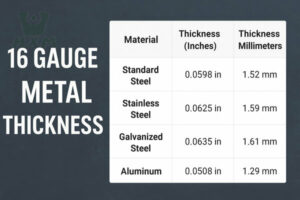

Technical Properties: The Data Every Buyer Must Know

Making an informed purchasing decision starts with accurate data. Here are the key specifications for 3003 aluminum, translated into the procurement advantages that matter to your bottom line.

| Property | Typical Specification | Procurement Advantage (Why This Matters to You) |

| Chemical Composition | Al: Balance, Mn: 1.0-1.5%, Cu: 0.05-0.20% | Guarantees Consistency: Our strict adherence to composition standards ensures every batch performs identically in your production line, minimizing downtime and waste. |

| Mechanical Properties | Tensile Strength: ~130 MPa (H14 Temper) <br> Yield Strength: ~125 MPa (H14 Temper) | Predictable Performance: You know exactly how the material will behave under forming and stress, ensuring the quality and durability of your final product. |

| Temper Designations | H14 (Half-Hard), H24 (Half-Hard, Strain-Hardened & Partially Annealed), O (Annealed) | Application Flexibility: We supply the right temper for your specific fabrication process, whether it’s for general forming (H14) or deep drawing complex parts (O-Temper). |

| Physical Properties | Density: ~2.73 g/cm³ (0.0986 lb/in³) | Accurate Costing & Logistics: Use this precise data to calculate material weight for accurate shipping quotes and to estimate your production yield per coil. |

Common Tempers of 3003 Aluminum

| Temper | Description | Typical Use |

|---|---|---|

| O | Annealed (soft) | Deep drawing, forming |

| H14 | Half-hard | Roofing, siding |

| H16 | Three-quarter hard | Panels, utensils |

| H18 | Full-hard | High-rigidity applications |

Huaxiao Metal maintains a full inventory of 3003-O, 3003-H14, and 3003-H16 aluminum sheets and coils, ready for immediate export.

Processing & Fabrication Tips

Forming: Excellent for deep drawing, spinning, or bending.

Machining: Moderate; use sharp tools to minimize built-up edges.

Welding: Excellent for gas, arc, and resistance welding.

Surface Treatment: Compatible with painting, anodizing, or powder coating for enhanced corrosion resistance and aesthetics.

Brazing: Excellent; widely used in HVAC applications.

Applications & Benefits: Where 3003 Alloy Drives Profitability

Understanding the technical data is one thing; seeing how it translates to business value is another. Here’s where 3003 alloy excels and how it can benefit your operation.

1. Benefit #1: Unlocks Manufacturing Efficiency & Reduces Costs

The outstanding formability of 3003 aluminum means it can be bent, stamped, and drawn with less force and a lower risk of cracking compared to stronger alloys. This translates to faster processing speeds, reduced wear on your tooling and machinery, and a lower scrap rate—all of which directly improve your manufacturing margins.

Ideal for: Cookware (pots, pans), HVAC components (fins, ductwork), lighting fixtures, and stamped equipment enclosures.

2. Benefit #2: Ensures Product Quality & Brand Reputation

Thanks to its excellent corrosion resistance, products made from 3003 aluminum are built to last. They withstand moisture and mild chemical exposure without rusting or significant degradation. For your business, this means a more durable final product, leading to higher customer satisfaction, fewer warranty claims, and a stronger brand reputation.

Ideal for: Chemical storage and transportation tanks, architectural siding and roofing, truck/trailer liners, and refrigerator panels.

3. Benefit #3: Provides Favorable Total Cost of Ownership (TCO)

3003 aluminum hits the “sweet spot” of performance and cost. It offers a significant step up in strength from the 1xxx series alloys, while being more economical than the higher-strength 5xxx series.

The Strategic Insight: Choosing 3003 aluminum minimizes your risk of over-engineering (and over-paying) with a higher-spec alloy when it’s not necessary. It allows you to meet performance requirements while protecting your budget.

3003 Aluminum vs. The Alternatives: Strategic Alloy Selection

Many procurement managers weigh the benefits of 3003 against other alloys. Making the right choice is crucial for controlling costs and ensuring performance.

3003 vs. 5052: Balancing Strength and Cost

| Feature | 3003 Aluminum (Al-Mn) | 5052 Aluminum (Al-Mg) | HXM Procurement Insight |

| Primary Alloy | Manganese (Mn) | Magnesium (Mg) | Choose 3003: If your project requires moderate strength, and the lowest possible material cost is a priority. |

| Strength | Medium-low (Moderate Strength) | High (Significantly higher, superior fatigue resistance) | Choose 5052: If the product demands better fatigue life and higher structural integrity (e.g., marine or aerospace components). |

| Saltwater Corrosion | Excellent (Suitable for general environments) | Superior (Marine Grade, excellent resistance to salt spray and saltwater) | Cost-Effectiveness: 3003’s corrosion resistance is adequate for most applications, offering a better price point. |

3003 vs. 1100: Formability and Strength

| Feature | 3003 Aluminum | 1100 Aluminum | Strategic Choice |

| Strength | Approximately 20% stronger than 1100 | Low (Commercially pure aluminum, lowest strength) | Choose 3003: To gain a significant mechanical property boost with minimal cost increase. |

| Formability | Excellent | Superb (Best formability) | Choose 1100: Only when the application requires the most extreme deep drawing or the absolute softest material. Otherwise, 3003 is the more balanced option. |

Sourcing Aluminum Alloy 3003: Your Supply Chain Partner

A material is only as good as the reliability of its supplier. At HXM Aluminum, we build partnerships by addressing the core concerns of every procurement professional.

1. Our Commitment to Quality & Consistency

We operate under strict quality control protocols (ISO 9001 certified). Every coil and sheet we ship can be accompanied by a material test certificate, giving you complete traceability, verification, and peace of mind.

2. Reliable Supply Chain & Inventory

We understand that production delays cost money. We maintain a robust inventory of standard 3003 gauges and tempers to support your just-in-time production schedules, helping you reduce your own warehousing costs and avoid stock-outs.

3. Flexible Product Forms & Customization

We deliver 3003 aluminum exactly how your production line needs it:

Coils: Custom widths and specified OD/ID to maximize your machine uptime.

Sheets & Plates: Precision cut-to-length services to minimize your drop and scrap.

Surface Options: Standard mill finish or with a protective PVC film to prevent surface scratches during your fabrication process.

FAQ

Our materials experts receive many questions about 3003 alloy aluminum. Here are some of the most common inquiries from procurement professionals:

Can 3003 aluminum alloy be welded?

Yes, 3003 aluminum alloy has excellent weldability. Typically, 1100 or 4043 electrodes are used for TIG or MIG welding to ensure weld strength and corrosion resistance.

What is the difference between H14 and O-Temper 3003?

They represent different tempers (hardness). O-Temper (annealed) is the softest temper and is suitable for deep drawing and complex forming; H14 (semi-hard) is the most common temper, offering moderate strength and good formability, making it suitable for general stamping and bending.

Is 3003 aluminum alloy resistant to seawater corrosion?

3003 has good atmospheric and general corrosion resistance, but its seawater resistance is not as good as that of 5000 series alloys such as 5052. If you are using it in a coastal or high-salinity environment, we recommend consulting our experts.

Is 3003 aluminum heat-treatable?

No. 3003 aluminum is non-heat-treatable and can only be strengthened through cold working.

Can 3003 aluminum be anodized?

Yes, but the resulting finish is not as bright as 5052 or 6061 due to its manganese content.

What factors influence the price of 3003 aluminum?

The price of 3003 aluminum primarily depends on three factors:

LME aluminum price: The international aluminum futures price serves as the benchmark cost.

Conversion fee: This fee depends on the required specifications (thickness, width) and processing accuracy.

Order volume: Bulk purchases typically yield more competitive quotes.

Can Huaxiao Metal (HXM) provide custom 3003 sizes?

Absolutely. We offer precision custom cutting services, providing 3003 aluminum sheets, strips, and bars in fixed widths and lengths according to your drawings or exact dimensional requirements.

Conclusion: Make the Smart, Strategic Choice

3003 aluminum isn’t just a commodity; it’s a smart, strategic raw material that expertly balances performance, cost, and manufacturability. Partnering with a supplier who understands both the material and your business needs is the key to unlocking its full value.

Ready to strengthen your supply chain? Request a competitive quote for your 3003 aluminum requirements today. Our dedicated team will respond promptly with pricing and lead times.

Have a technical question or need to verify a specification for your engineering team? Contact one of our material specialists for a free consultation.