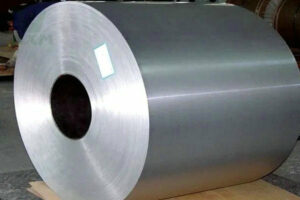

As the leading 1050 Aluminum Coil Suppliers, we are committed to providing superior 1050 Aluminum Coil to meet a variety of industrial needs. Our 1050 Aluminum Coil is known for its excellent corrosion resistance, processing performance, and economy, which is very suitable for manufacturing and processing.

Whether you are looking for competitive 1050 Aluminum Coil Prices or want to learn about our 1050 Aluminum Coil For Sale options, we can provide you with a comprehensive solution. Contact us now to get the latest 1050 Aluminum Coil prices and customized services to meet all your Aluminum Coil needs.

1050 Aluminium Coils Specifications

Standards : ASTM B209 / ASME SB209, etc.

Temper: O, H12, H14, H18, H24, H111, etc.

Thickness: 0.2~300mm

Width: 500~2500mm

Surface: Bright, polished, hairline, brush, sand blast, checkered, embossed, etching, etc

Finish: Mill, Customer specific finish

Delivery Time: 7-20 days.

1050 Aluminium Coil Product Performance

High Purity: With 99.5% aluminum content, it ensures excellent corrosion resistance and good workability.

Excellent Corrosion Resistance: Performs well in both atmospheric and aqueous environments.

Good Electrical Conductivity: Suitable for electrical applications, including conductors and transformers.

High Thermal Conductivity: Effective for heat exchangers and thermal applications.

Excellent Formability: Easily shaped and formed, suitable for various fabrication processes.

Non-Toxic and Safe: Suitable for food and chemical handling applications.

HXMA manufactures and wholesales 1050 Aluminium Coils in various sizes and states with competitive prices and fast shipping, and also provides customized services to meet different customers’ requirements.

Contact us for the 1050 aluminum coil price, We are looking forward to your inquiry!

1050 Aluminium Coils Data Sheet

Chemical Composition of Aluminum Coil 1050

| Al | Mn | Fe | Cu | Zn | Si | Ti |

|---|---|---|---|---|---|---|

| 99.5 | 0.05 | 0.4 | 0.05 | 0.05 | 0.25 | 0.03 |

Mechanical Properties of Aluminium Coil 1050

| Mechanical Properties | Typical Values |

|---|---|

| Tensile Strength (MPa) | 70-105 |

| Yield Strength (MPa) | 20-35 |

| Elongation (%) | 25-35 |

| Hardness (Brinell) | 30-35 HB |

Physical Properties of Aluminum Coil 1050

| Physical Property | Value |

|---|---|

| Density (g/cm³) | 2.71 |

| Melting Point (°C) | 650-660 |

| Thermal Conductivity (W/m·K) | 230 |

| Electrical Conductivity (%IACS) | 60-61 |

Tempers of 1050 Aluminium Coil

| Tempers | Description |

|---|---|

| H12 | Strain hardened, 1/4 hard |

| H14 | Strain hardened, 1/2 hard |

| H16 | Strain hardened, 3/4 hard |

| H18 | Strain hardened, full hard |

1050 Aluminum Coil Tempers

The 1050 aluminum coil is available in various tempers, each offering different mechanical properties and performance characteristics suited to specific applications. Here are the common tempers for 1050 aluminum coils:

H14: This temper provides a medium strength level with good formability. It is commonly used in applications requiring moderate strength and resistance to deformation, such as in manufacturing aluminum panels and automotive parts.

H24: Similar to H14, the H24 temper offers slightly higher strength and hardness. It is used in applications that require improved strength while still maintaining good ductility and corrosion resistance, such as in architectural applications and various industrial components.

O: The O temper represents fully annealed aluminum, offering maximum softness and ductility. It is ideal for applications where extensive forming and bending are required, such as in the production of thin-walled parts and intricate shapes.

H18: This temper provides a higher strength compared to H14 and H24 but with reduced formability. It is used in applications where high strength and rigidity are critical, such as in structural components and high-stress environments.

H12: This temper offers a balance between strength and formability. It is used in applications that require moderate strength and good workability, such as in the production of household appliances and various industrial parts.

Each state of 1050 aluminum coil is designed to meet specific performance requirements, so choosing the right state depends on your application’s needs for strength, formability, and other mechanical properties.

If you have any questions, you can contact us directly!

1050 Aluminum Coils Application

1050 Aluminum Coils are part of the 1000 series aluminum alloys, which are known for their high purity, excellent corrosion resistance, and good electrical and thermal conductivity. These properties make 1050 Aluminum Coils suitable for a wide range of applications across various industries.

1. Electrical Industry

2. Chemical and Food Processing Industry

3. Heat Exchangers

4. Architectural Applications

5. Packaging Industry

6. Automotive Industry

7. General Fabrication

The versatility and performance of the 1050 aluminum coil make it the material of choice in numerous applications where high purity, corrosion resistance, and good electrical conductivity are critical.

For more information or 1050 aluminum coil pricing, please contact HXM and our team will get back to you within 24 hours!

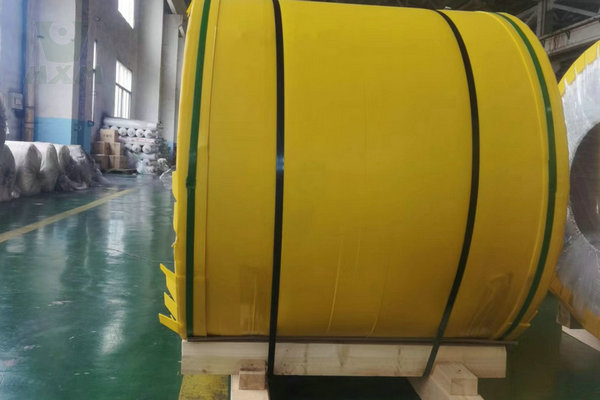

1050 Aluminum Coil Packages

The following is our company’s standard aluminum coil export packaging. If the customer has any packaging requirements, our company can meet them.