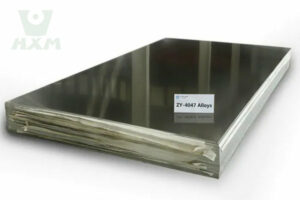

6061 Aluminium Sheets Supplier | HXM-Aluminum

Often referred to as the “workhorse alloy,” 6061 aluminium sheet is one of the most widely used heat-treatable aluminum alloys. Its unique combination of strength, corrosion resistance, and machinability make it ideal for a wide range of applications, from aerospace components to building structures.

HXM-Aluminum is your trusted global partner for high-quality 6061-T6 aluminum sheet, fully certified and cut to your precise requirements.

6061 Aluminium Sheets Specifications

Standards: ASTM, ASME, AMS, GB/T, JIS

Thickness: 0.2-200mm, etc.

Width: 500-3100mm, etc.

Length: Customized

Material Temper: F, O, T4, T6, T651, H112

Delivery Time: 7-20 days.

Product Performance

6061 aluminium sheet metal is a high-quality alloy product produced by heat treatment and pre-stretching. Although its strength cannot be compared with that of 2000 series alloys or 7000 series alloys, the composition of 6061 aluminum alloy is mainly Mg and Si, so 6061 aluminium alloy sheet shows excellent processing performance, excellent weldability and electroplating, and good corrosion resistance , high toughness and other characteristics. It is worth mentioning that the 6061 aluminium alloy plate has a dense structure and will not deform after processing.

HXMA manufactures and wholesales 6061 Aluminium Sheets in various sizes and states with competitive prices and fast shipping, and also provides customized services to meet different customers’ requirements.

HXMA Metal is a 6061 aluminium sheet manufacturer and exporter for 15 years. Our company has advanced production equipment and a professional production team. In order to ensure the quality of products shipped, we have a formal QC department. Reserve 20 tons of 6061 aluminium sheet stock all year round. Contact us for 6061 aluminium sheet price, looking forward to your inquiry!

Sheet Aluminium 6061 Data Sheet

Chemical Composition of 6061 Aluminum Sheet

| Elements | Mg | Fe | Cu | Mn | Si | Cr | Ti | Zn | Others | Al |

| Content | 0.8-1.2 | 0.70 | 0.15-0.40 | 0.15 | 0.40-0.8 | 0.04-0.35 | 0.15 | 0.25 | 0.05 | Remains |

Mechanical Properties and Tempers of 6061 Aluminium Sheet

| Typical Mechanical Properties of 6061 Aluminium Sheet | |||

| Temper | Tensile Strength | Yield Strength | Elongation |

| KSI | KSI | % | |

| T451 | 35 | 21 | 25 |

| T651 | 45 | 40 | 17 |

Different Tempers of 6061 Aluminum Sheet Metal

6061 aluminum alloy is a commonly used aluminum alloy that can be used to manufacture a variety of products, including sheet metal products. It can be processed in different states to obtain different mechanical properties and uses. The following are several common states of 6061 aluminum sheet metal:

T6 6061 Aluminum Sheet: This is one of the most common states in 6061 aluminum sheet metal. In the T6 state, the aluminum alloy undergoes high-temperature solution treatment and then is rapidly quenched. This process gives it high strength and hardness. 6061 aluminum in T6 temper is commonly used in structural applications where strength is critical.

T4 6061 Aluminum Sheet: In this state, the aluminum alloy has been solid solution treated and then aged naturally. It offers good formability and weldability while still possessing reasonable strength. 6061 aluminum in T4 temper is typically used in applications that require forming or bending.

T651 6061 Aluminum Sheet: Similar to the T6 condition, but with additional stretching after solution treatment. This stretching process reduces internal stress and enhances dimensional stability. 6061 aluminum in T651 condition is typically used in applications requiring precision parts and components where tight tolerances are required.

O 6061 Aluminum Sheet: This is the annealed state of 6061 aluminum, completely softened. It has excellent formability but is less strong than in the processed state. 6061 aluminum in the O temper is suitable for applications where extensive forming is required or where strength is not a primary consideration.

T6511 6061 Aluminum Sheet: This is a stretched version of the T651 condition, achieved through a stretching process. It offers properties similar to T651 aluminum, but with improved flatness and straightness. 6061 aluminum in the T6511 temper is typically used in applications where flatness is critical, such as aerospace components.

These are some of the most common states of 6061 aluminum sheets, but there are others available, each offering specific properties suitable for different applications.

6061 Aluminum Sheet Application

- Aerospace

- Car

- Architecture

- Transportation and Logistics

- Electronics and Electrical

- Sports and Entertainment

- Ship Building

- Military and Defense

- Industrial Manufacturing

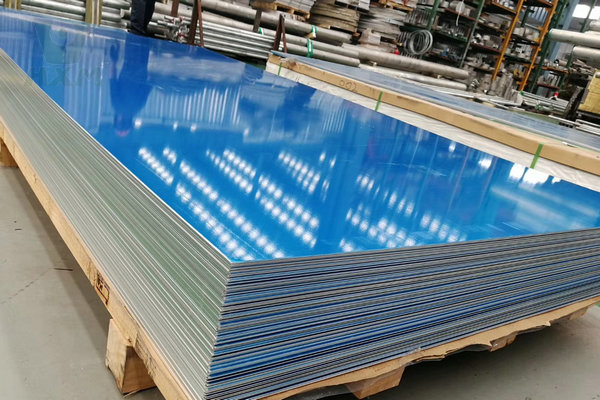

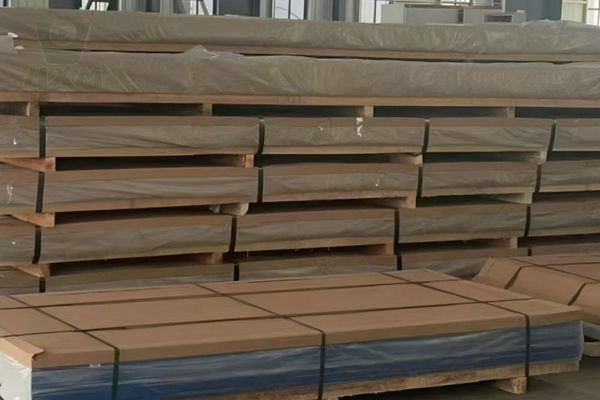

6061 Aluminum Sheet Packages

The following is our company’s conventional export packaging for aluminum plates. If you have special packaging requirements, our company can meet them. We very much hope to become one of your aluminum plate suppliers!

Why Source 6061 Aluminium Sheets from HXM-Aluminum?

Consistent T6 Temper

We guarantee the proper T6 temper (solution heat-treated and artificially aged) for optimal strength and machinability, ensuring predictable performance in your operations.

Precision Cutting Services

Our advanced cutting equipment allows us to supply 6061 sheets cut to your exact dimensions with tight tolerances, saving you time and reducing material waste.

Comprehensive Stock

We maintain a large inventory of standard 6061-T6 sheet sizes and thicknesses, ready for immediate dispatch to meet your project deadlines.

Full Traceability & Certification

Every sheet is supplied with a Mill Test Certificate (MTC), providing complete traceability and assurance that it meets international standards like ASTM B209 and EN 485.

Frequently Asked Questions

What is the difference between 6061-T6 and 5052 aluminum sheet?

6061-T6 is stronger and harder due to being heat-treatable, making it ideal for structural applications. 5052 is more formable and has better saltwater corrosion resistance, making it excellent for sheet metal work, especially in marine environments. We can help you choose the right one.

5052 Aluminum vs 6061 Aluminum

Can I get my 6061 sheets with a protective PVC film?

Yes. We highly recommend PVC film coating, especially for sheets with a fine finish. It protects the surface from scratches during fabrication and transport. Just specify this requirement in your inquiry.

Is 6061 aluminum good for anodizing?

Yes, 6061 provides a good surface for anodizing, which can be done for protective or decorative purposes.