HXM offers premium 1050 aluminum wire, a line of products engineered to deliver superior performance in electrical, thermal, and industrial applications. With an aluminum content of up to 99.5%, 1050 aluminum wire offers exceptional corrosion resistance, excellent ductility, and excellent electrical conductivity.

Looking for a 1050 aluminum wire supplier? Contact us today to learn more about 1050 aluminum wire pricing, availability, and customization options.

1050 Aluminium Wires Specifications

Diameter: 0.5mm-15mm

Length: Roll

Alloy Temper: O, H12, H14, H16, H18, H22, H24, H26, H28, ect.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: BS 5L36, AMS-QQ-A-225/1, ASTM B211, etc

Delivery Time: 7-20 days.

1050 Aluminum Wire Product Performance

High Purity (99.5%): Ensures exceptional corrosion resistance and conductivity.

Superior Ductility: Ideal for applications requiring forming, bending, or drawing.

Lightweight and Durable: Combines low density with excellent mechanical performance.

Environmentally Friendly: Fully recyclable material, reducing environmental impact.

HXM manufactures and wholesales 1050 Aluminium Wires in various sizes and states with competitive prices and fast shipping, and also provides customized services to meet different customers’ requirements.

Contact us for the 1050 aluminum wire price, We are looking forward to your inquiry!

1050 Aluminium Wires Data Sheet

Chemical Composition of 1050 Aluminum Wire

| Al | Mn | Fe | Cu | Zn | Si | Ti |

|---|---|---|---|---|---|---|

| 99.5 | 0.05 | 0.4 | 0.05 | 0.05 | 0.25 | 0.03 |

Mechanical Properties of 1050 Aluminium Wire

| Temper Code | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| O (Annealed) | 60 – 100 | ≥ 25 | 35 – 50 | 20 – 30 |

| H12 (1/4 Hard) | 80 – 100 | 35 – 45 | 15 – 25 | 35 – 40 |

| H14 (1/2 Hard) | 100 – 120 | 50 – 60 | 10 – 20 | 45 – 50 |

| H18 (Full Hard) | 120 – 130 | 60 – 80 | 2 – 10 | 55 – 60 |

| F (As-Fabricated) | 60 – 90 | 25 – 40 | 40 – 50 | 20 – 30 |

Physical Properties of 1050 Aluminum Wire

| Physical Property | Value |

|---|---|

| Density (g/cm³) | 2.71 |

| Melting Point (°C) | 650-660 |

| Thermal Conductivity (W/m·K) | 230 |

| Electrical Conductivity (%IACS) | 60-61 |

Tempers of 1050 Aluminium Wire

| Tempers | Description |

|---|---|

| H12 | Strain hardened, 1/4 hard |

| H14 | Strain hardened, 1/2 hard |

| H16 | Strain hardened, 3/4 hard |

| H18 | Strain hardened, full hard |

1050 Aluminum Wire Application

Electrical Wiring: High conductivity makes it ideal for power transmission.

Thermal Conductors: Used in heat exchangers, radiators, and thermal systems.

Industrial Components: Perfect for rivets, fasteners, and mechanical parts.

Decorative Items: Suitable for crafting and artistic designs.

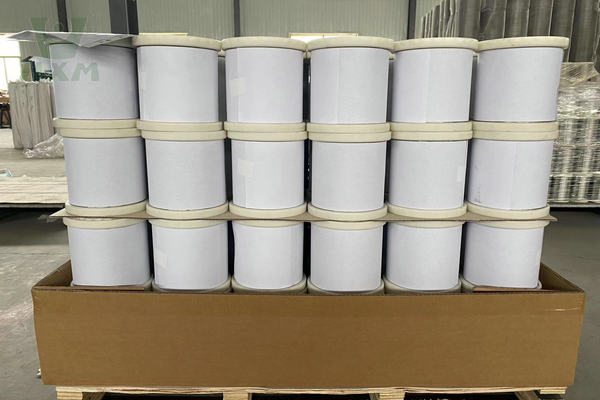

1050 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.