1070 aluminum wire is a high-purity aluminum wire with an aluminum content of up to 99.70%. It is widely used in many fields such as electrical, power, electronics, and chemical industries due to its excellent electrical conductivity, thermal conductivity, good formability, and excellent corrosion resistance. Its high purity characteristics make it particularly important in applications that require high-quality aluminum materials, especially in situations where high electrical conductivity and durability are required.

If you are looking for a 1070 aluminum wire supplier, please contact us to get the most competitive aluminum wire price and delivery time.

1070 Aluminium Wires Specifications

Diameter: 0.5mm-50mm

Length: Roll

Alloy Temper: HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,T651,T3,T451, T4,T6, ect.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

Certificate: ISO9001, CE, SGS, etc

Delivery Time: 7-20 days.

1070 Aluminum Wire Product Performance

High purity: 1070 aluminum wire contains up to 99.70% aluminum, ensuring excellent conductivity and corrosion resistance.

Excellent conductivity: Its conductivity reaches 61% IACS, making it an ideal choice for the power and electronics industries.

Strong corrosion resistance: It is particularly suitable for environments that require corrosion resistance, such as chemical processing and areas with high humidity.

Wide application: It is suitable for use in power transmission, electronic appliances, construction and many other fields.

Contact us for the 1070 aluminum wire price, We look forward to your inquiry!

1070 Aluminium Wires Data Sheet

Chemical Composition of 1070 Aluminum Wire

| Al | Fe | Si | Cu | Zn | Mn | Mg | Ti | Others |

|---|---|---|---|---|---|---|---|---|

| 99.7 | 0.25 | 0.20 | 0.04 | 0.04 | 0.03 | 0.03 | 0.03 | 0.03 (Each) |

Mechanical Properties of 1070 Aluminium Wire

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 55-95 |

| Yield Strength (MPa) | 20-30 |

| Elongation (%) | 20-30 |

| Hardness (Brinell) | 23 |

Physical Properties of 1070 Aluminum Wire

| Physical Property | Value |

|---|---|

| Density (g/cm³) | 2.70 |

| Melting Point (°C) | 643 |

| Thermal Conductivity (W/m·K) | 229 |

| Electrical Conductivity (%IACS) | 61 |

Tempers of 1070 Aluminium Wire

| Temper | Description |

|---|---|

| O | Annealed, recrystallized (soft) |

| H12 | Strain hardened, 1/4 hard |

| H14 | Strain hardened, 1/2 hard |

| H16 | Strain hardened, 3/4 hard |

| H18 | Strain hardened, full hard |

This table illustrates the various tempers of 1070 aluminum wires, indicating the level of hardness achieved through different heat treatment processes.

1070 Aluminum Wire Application

1070 aluminum wire is widely used in many fields due to its high purity and good electrical conductivity, especially in the following industries and scenarios:

Power industry: used for power transmission, distribution lines, transformer wiring, etc.

Electronic industry: used as wire material in electronic products, widely used in circuit boards, wiring, etc.

Chemical industry: used in parts of chemical equipment that require high corrosion resistance.

Construction and transportation: suitable for construction and transportation fields that require high conductivity and low corrosion.

Automation equipment: as a connecting wire in the automation control system, it provides efficient and stable current conduction.

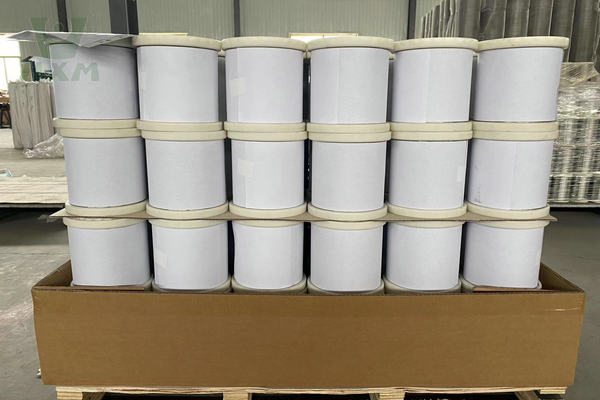

1070 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.