High-Quality 6061 Aluminum Wires

Are you looking for 6061 aluminum wire for your project? Our high-quality 6061 aluminum wire is competitively priced, available in stock, and customizable. As one of the leading aluminum wire suppliers and manufacturers, we offer fast delivery and customization services to meet your needs.

Our 6061 wire is ideal for a wide range of applications, from fasteners and rivets to electrical components.

Excellent Strength & Weldability

Custom Diameters & Tempers (T4, T6, T651)

Conforms to ASTM B211 & AMS 4102 Standards

Global Shipping & Competitive Pricing

6061 Aluminum WireSpecifications

As a premier supplier, HXM Aluminum provides 6061 aluminum wire in a wide range of specifications to meet your exact project requirements.

Diameter: 0.13mm-15mm

Length: Roll

Alloy Temper: O, T4, T6, T651, etc.

Craft: Cutting, hemming, arc bending, welding, grinding, spraying, forming

Surface: Mill finish, no stains, without rough selvage, Anodizing

International Standards: ASTM B211, AMS 4102, GB/T 3191, etc.

Standard: AMS 4116 6061-T4 aluminum wire, AMS 4115 6061-O aluminum wire, AMS 4117 6061-T6 aluminum wire, ASTM B211, EN 573, ISO 6361, etc.

Delivery Time: 7-20 days.

(A96061) 6061 Aluminum Wire Data Sheet

Understanding the technical data is crucial for engineers and professional buyers. Here are the detailed chemical and mechanical properties of our 6061 aluminum wire.

Chemical Composition of 6061 Aluminum Wire

| Elements | Mg | Fe | Cu | Mn | Si | Cr | Ti | Zn | Others | Al |

| Content | 0.8-1.2 | 0.70 | 0.15-0.40 | 0.15 | 0.40-0.8 | 0.04-0.35 | 0.15 | 0.25 | 0.05 | Remains |

Mechanical Properties and Tempers of 6061 Aluminium Wire

| Property | 6061-O (Annealed) | 6061-T4 (Solution Heat-Treated) | 6061-T6 (Solution & Artificially Aged) |

|---|---|---|---|

| Ultimate Tensile Strength | 124 MPa (18 ksi) | 207 MPa (30 ksi) | 290 MPa (42 ksi) |

| Yield Strength | 55 MPa (8 ksi) | 110 MPa (16 ksi) | 241 MPa (35 ksi) |

| Elongation at Break | 25-30% | 16-20% | 8-10% |

| Hardness (Brinell) | ~30 HB | ~60 HB | ~95 HB |

| Fatigue Strength | 62 MPa (9 ksi) | 96 MPa (14 ksi) | 110 MPa (16 ksi) |

| Modulus of Elasticity | 68.9 GPa (10,000 ksi) | 68.9 GPa (10,000 ksi) | 68.9 GPa (10,000 ksi) |

Different Tempers of 6061 Aluminum Wires Metal

6061 aluminum alloy is a commonly used aluminum alloy that can be used to manufacture a variety of products, including sheet metal products. It can be processed in different states to obtain different mechanical properties and uses. The following are several common states of 6061 aluminum wire metal:

T6: This is one of the most common states in 6061 aluminum wire metal. In the T6 state, the aluminum alloy undergoes high-temperature solution treatment and then is rapidly quenched. This process gives it high strength and hardness. 6061 aluminum in T6 temper is commonly used in structural applications where strength is critical.

T4: In this state, the aluminum alloy has been solid solution treated and then aged naturally. It offers good formability and weldability while still possessing reasonable strength. 6061 aluminum in T4 temper is typically used in applications that require forming or bending.

T651: Similar to the T6 condition, but with additional stretching after solution treatment. This stretching process reduces internal stress and enhances dimensional stability. 6061 aluminum in T651 condition is typically used in applications requiring precision parts and components where tight tolerances are required.

O: This is the annealed state of 6061 aluminum, completely softened. It has excellent formability but is less strong than in the processed state. 6061 aluminum in the O temper is suitable for applications where extensive forming is required or where strength is not a primary consideration.

T6511: This is a stretched version of the T651 condition, achieved through a stretching process. It offers properties similar to T651 aluminum, but with improved flatness and straightness. 6061 aluminum in the T6511 temper is typically used in applications where flatness is critical, such as aerospace components.

These are some of the most common states of 6061 aluminum wires, but there are others available, each offering specific properties suitable for different applications.

Applications of 6061 Aluminum Wire Metal

6061 aluminum wire is used in a wide variety of industries due to its excellent properties. Common applications include:

Electrical and Conductive Components: Great for wires and conductors.

Automotive and Aerospace: Used for lightweight structural components and fasteners.

Architectural: Good for tension wires, brackets, and supports.

Industrial Uses: Used in machinery, tools, and welding rods.

Arts and Crafts: Often used to create sculptures and custom designs.

If the above is not your industry, it does not mean that 6061 aluminum wire is not suitable. You can contact us directly and we will discuss what performance you need from the aluminum wire and find the aluminum wire suitable for your industry.

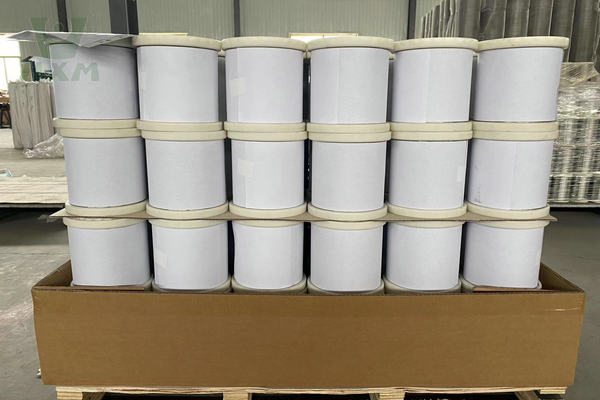

6061 Aluminum Wire Packages

The following is our company’s standard aluminum wire export packaging. If the customer has any packaging requirements, our company can meet them.

Why Choose HXM Aluminum as Your Supplier?

We are more than just a manufacturer; we are your reliable partner in the aluminum supply chain.

ISO 9001 Certified: Our manufacturing processes adhere to strict international quality standards, ensuring you receive a consistently high-quality product.

Large Inventory & Fast Delivery: We maintain a large stock of common 6061 wire specifications for immediate dispatch, reducing your project lead times.

Full Customization: Need a specific diameter, temper, or packaging? Our technical team is ready to meet your custom requirements.

Rigorous Quality Control: From raw material analysis to final dimensional checks, every batch undergoes a multi-step inspection process.

Experienced Export Team: We have years of experience shipping aluminum products globally, guaranteeing smooth customs clearance and reliable delivery to your port.

FAQ

What Is 6061 Aluminum Wire?

6061 aluminum wire is a versatile product made from one of the most popular aluminum alloys on the market. Known for its excellent corrosion resistance, high strength-to-weight ratio, and good machinability, it is suitable for a wide range of industrial and commercial applications. The alloy consists primarily of aluminum, with magnesium and silicon as its main alloying elements, giving it excellent mechanical properties.

Features of 6061 Aluminum Wire:

High Strength: Offers excellent mechanical strength, making it suitable for demanding applications.

Corrosion Resistance: Performs well in marine and industrial environments due to its natural resistance to rust.

Good Weldability: Can be welded using common techniques, ensuring structural integrity.

Versatility: Easily machined, cut, and formed for custom applications.

Durable: Resistant to wear and tear, ensuring long-lasting performance.

What are the advantages of 6061 aluminum wire?

6061 aluminum wire offers a balance of high strength, corrosion resistance, and good machinability, making it ideal for industrial and commercial applications.

Superior Strength and Machinability

6061 aluminum wire is a precipitation-hardened alloy, containing magnesium and silicon as its major alloying elements. It offers excellent mechanical properties and is easily machined in the T6 and T4 tempers, making it a preferred choice for parts requiring high strength.

Excellent Corrosion Resistance

This wire exhibits very good corrosion resistance to atmospheric conditions and good resistance to seawater. It forms a protective oxide layer that prevents further corrosion, ensuring longevity and durability.

Great Weldability and Formability

6061 aluminum wire can be readily welded using techniques like Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG). In its annealed condition (O-temper), it offers good formability for bending and cold-working operations.

Why Choose Us As Your 6061 Aluminum Wire Supplier?

Competitive Prices

We work directly with top manufacturers to offer the best prices for 6061 aluminum wire. Request a quote today to compare.

Trusted Aluminum Metal Suppliers

Our products meet international standards, ensuring you receive reliable and high-quality materials.

Extensive Stock

We maintain a large inventory of 6061 aluminum wire to provide fast delivery for both small and bulk orders.

Custom Manufacturing Services

We offer cutting, shaping, and packaging options to meet your unique requirements.

Global Shipping

With efficient logistics, we deliver to customers worldwide, ensuring quick and safe transportation.

Which temper of 6061 wire is best for my application?

It depends on your needs. T6 temper offers the highest strength and is ideal for structural parts. T4 temper provides good strength with better formability than T6. O temper (annealed) is the softest and most formable, suitable for complex bending or drawing operations before any subsequent heat treatment.

What is the main difference between 6061 and 5052 aluminum wire?

The main difference is in their primary alloying elements and properties. 6061 is alloyed with magnesium and silicon, is heat-treatable, and offers higher strength. 5052 is alloyed with magnesium, is non-heat-treatable, and offers superior corrosion resistance (especially in marine environments) and formability.

What is the MOQ (Minimum Order Quantity) for 6061 aluminum wire?

Our typical MOQ for standard 6061 aluminum wire is 500 kgs. However, this can vary based on stock availability and custom requirements. Please contact us with your specific needs.