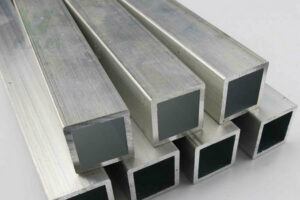

1060 Aluminum Tubes Suppliers & Manufacturers

We offer 1060 aluminum tubes that meet strict international quality standards, focusing on durability, corrosion resistance, and precise dimensions. Our experienced team can assist with customization, bulk orders, and technical support.

1060 Aluminum Tube is a high purity aluminum alloy product that has excellent corrosion resistance, good electrical conductivity, and superior processing properties. The alloy has an aluminum content of 99.6% or higher and is widely used in a variety of industries, including electrical, chemical, and construction applications. If you are looking for 1060 Aluminum Tube suppliers, manufacturers, or price details, please contact us directly. Contact us today for a custom quote or more information about our 1060 aluminum alloy pipe products.

1060 Aluminium Tubes Specifications

Standards: ASTM B345, B210, B241, B313, B429 / ASME SB345, SB210, SB241, SB313, SB429, etc.

Thickness: 0.2-500mm, etc.

Width: 20-2650mm, etc.

Length: Customized

Material Temper: F, O, H12, H14, H16, etc.

Delivery Time: 7-20 days.

1060 Aluminum Tube Product Performance

1060 Aluminum Tube is a high-purity aluminum alloy with 99.6% aluminum content, which has excellent corrosion resistance, excellent thermal and electrical conductivity, and excellent ductility. It is well suited for industries such as electrical, food, chemical, and construction, which require high corrosion resistance and lightweight materials without high mechanical strength.

- Corrosion Resistance: It has strong corrosion resistance in a variety of environments, especially when exposed to the atmosphere and seawater.

- Thermal and Electrical Conductivity: With excellent electrical conductivity, it is suitable for electrical and thermal applications, including heat exchangers and conductors.

- Forgeability and Machinability: It is known for its excellent machinability and is well-suited for bending, forming, and machining to meet the needs of complex designs and shapes.

Huaxiao Metal manufactures and wholesales 1060 aluminum tubes in various sizes and states at competitive prices and fast shipping. It also provides customized services to meet different customers’ requirements.

Are you looking for the best 1060 Aluminum Tube prices? Contact Huaxiao Metal, a reputable 1060 Aluminum Tube manufacturer and supplier, to get a quote today. Prices may vary based on quantity, size, and finish. Bulk orders are often discounted, so contact us to compare quotes and ensure you get the best price. We look forward to your inquiry!

Aluminum Tube

1060 Aluminium Tubes Data Sheet

1060 Aluminium Alloy Pipes Equivalent Grades

| STANDARD | UNS |

| Aluminium 1060 | A91060 |

Chemical Composition of 1060 Aluminum Alloy Pipe

| Element | Al | Mn | Fe | Cu | Zn | Si | Ti |

|---|---|---|---|---|---|---|---|

Composition(%) | 99.6 | 0.03 | 0.35 | 0.05 | 0.03 | 0.25 | 0.03 |

Mechanical Properties of 1060 Aluminium Alloy Pipe

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength (MPa) | 55-95 |

| Yield Strength (MPa) | 15 |

| Elongation (%) | 25-30 |

| Hardness (Brinell) | 30 |

Physical Properties of 1060 Aluminum Tube

| Physical Property | Value |

|---|---|

| Density (g/cm³) | 2.7 |

| Melting Point (°C) | 660 |

| Thermal Conductivity (W/m·K) | 230 |

| Electrical Conductivity (%IACS) | 62 |

Tempers of 1060 Aluminium Tube

Here are the tempers of the 1060 aluminium tubes presented in a table:

| Temper | Description |

|---|---|

| O | Annealed, recrystallized (soft) |

| H12 | Strain hardened, 1/4 hard |

| H14 | Strain hardened, 1/2 hard |

| H16 | Strain hardened, 3/4 hard |

| H18 | Strain hardened, full hard |

This table illustrates the various tempers of 1060 aluminium tubes, indicating the hardness level achieved through different heat treatment processes.

1060 Aluminum Tube is a versatile and cost-effective aluminum alloy that can be used in a variety of industries. When choosing a 1060 Aluminum Tube supplier and manufacturer, consider factors such as quality assurance, pricing, and delivery reliability. If you are looking for 1060 Aluminum Tube for sale, contact a trusted supplier to get the best prices and high-quality products.

For more information on 1060 Aluminum Tube prices, specifications, and availability, contact us today!

1060 Aluminum Tube Application

Heat Exchangers and Radiators: High thermal conductivity makes it suitable for heat dissipation systems.

Electrical Conduction: Commonly used in bus bars, conductors, and other components requiring high electrical conductivity.

Food and Chemical Processing: The purity and corrosion resistance ensure safety in contact with food and chemicals.

Architectural and Decorative Use: Ideal for structures and decorative applications due to its corrosion resistance and aesthetic appeal.

If you are looking for 1060 Aluminum Tube for sale, Huaxiao Metal is a trusted manufacturer and supplier. Whether you need a small or large quantity order, we can provide high-quality 1060 aluminum alloy pipe products at competitive prices.

1060 Aluminum Tube Packages

The following is our company’s standard aluminum pipe & tube export packaging. If the customer has any packaging requirements, our company can meet them.