5052 Aluminum Tube is widely used in industries such as marine, automotive, and construction due to its strong resistance to saltwater corrosion and excellent strength. The alloy contains magnesium and chromium as the main elements, which enhance its durability and flexibility.

HXM-Aluminum is proud to be a leading aluminum supplier and manufacturer of 5052 Aluminum tubes, ensuring that our products meet strict quality standards and are available at competitive prices.

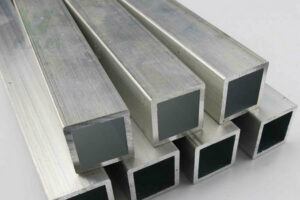

5052 Aluminum Pipe & Tube Specifications

Standards: AMS4071 | AMS-WW-T-700/4 | ASTM B210 | BS EN 573 | BS EN 755 | BS EN 754, etc.

Thickness: 0.2-500mm, etc.

Width: 20-2650mm, etc.

Length: Customized

Shape: Round, Square, Rectangular, etc.

Material Temper: F, O, T4, T6, T651, H14, H112, etc.

Delivery Time: 7-20 days.

5052 Aluminum Tube Metal Data Sheet

Equivalent Grades Of 5052 Aluminum Pipes

Here’s a concise table showing the equivalent grades and standards for 5052 aluminum pipe:

| Standard/Grade | Equivalent Grade | Key Features | Applications |

|---|---|---|---|

| 5052 (US Standard) | 5052 | Excellent corrosion resistance, good strength, and workability | Marine, automotive, construction |

| EN AW-5052 (European Standard) | EN AW-5052 | Same properties as 5052 | Same as 5052 |

| JIS A5052 (Japanese Standard) | JIS A5052 | Same properties as 5052 | Same as 5052 |

| GB 5052 (Chinese Standard) | GB 5052 | Same properties as 5052 | Same as 5052 |

Chemical Composition of 5052 Aluminum pipe

Here’s the chemical composition of the 5052 aluminum pipe displayed in a horizontal table format using element symbols:

| Element | Al | Mg | Cr | Mn | Cu | Si | Fe | Zn | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | Balance | 2.2 – 2.8 | 0.15 – 0.35 | 0.10 – 0.50 | ≤ 0.10 | ≤ 0.25 | ≤ 0.40 | ≤ 0.10 | Each ≤ 0.05 |

Mechanical Properties of 5052 Aluminium Pipes with Different Tempers

Temper | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

5052-O (Annealed) | 65 – 115 | 130 – 185 | 25 – 40 | 30 – 50 |

5052-H32 | 210 – 250 | 260 – 300 | 12 – 20 | 60 – 80 |

5052-H34 | 230 – 260 | 270 – 310 | 10 – 18 | 65 – 85 |

5052-H36 | 240 – 270 | 280 – 320 | 8 – 16 | 70 – 90 |

5052-H38 | 250 – 280 | 290 – 330 | 6 – 14 | 75 – 95 |

For high-quality 5052 aluminum pipes and professional assistance, contact HXM, your reliable supplier of aluminum products.

Different Tempers of 5052 Aluminum Pipes Metal

O (Annealed): This temper provides the highest ductility and lowest strength. It is used in applications requiring good formability and minimal strength.

H32: Offers a balance between strength and ductility. It is used in applications where moderate strength and good formability are required.

H34: Provides higher strength compared to H32 with slightly lower ductility. Suitable for applications requiring increased strength.

H36: Further increased strength and reduced ductility compared to H34. Used in applications needing high strength and some degree of formability.

H38: The highest strength temper, with reduced elongation. It is used in applications where maximum strength is critical.

5052 Aluminum Tubes Application

5052 aluminum tubes are highly versatile and suitable for a broad array of applications due to their strength and resistance to corrosion. Common uses include:

Marine Industry: Boat fittings, handrails, and other structures exposed to saltwater.

Automotive Industry: Fuel tanks, piping, and structural components that require lightweight and durable materials.

Construction Sector: Architectural elements, railings, and frames where corrosion resistance is essential.

Refrigeration and Cooling Systems: Tubes are used in cooling systems due to their excellent thermal conductivity.

General Industrial Use: Pneumatic and hydraulic systems, heat exchangers, and other machinery components.

5052 Aluminum Pipe & Tube Packages

The following is our company’s standard aluminum pipe & tube export packaging. If the customer has any packaging requirements, our company can meet them.

FAQ

Are 5052 aluminum tubes suitable for welding?

Yes, 5052 aluminum tubes can be welded using appropriate techniques, ensuring the preservation of their mechanical properties.

What industries commonly use 5052 aluminum tubes?

5052 aluminum tubes are widely used in marine, automotive, and construction industries due to their strong resistance to corrosion and good workability.

Why Choose Us As Your 5052 Aluminum Pipe Supplier?

Superior Quality: Our tubes are manufactured using state-of-the-art technology to deliver consistent performance.

Corrosion Resistance: Ideal for applications exposed to marine and harsh environmental conditions.

Customization: We provide customizable solutions to fit unique project requirements.

Competitive Pricing: Our 5052 aluminum tube prices are competitive, ensuring value without compromising on quality.

Extensive Stock: We maintain robust inventory levels to minimize lead times and meet client deadlines.

How do I choose the right supplier for 5052 aluminum tubes?

Look for experienced suppliers and manufacturers with a reputation for quality and reliability. HXM-Aluminum’s expertise and extensive inventory make us a preferred choice for clients seeking 5052 aluminum tubes at competitive prices.